Custom Electronic Assembly Manufacturing Solutions

NPI Solutions is your one-stop-shop for Electro-mechanical manufacturing, design, and engineering.

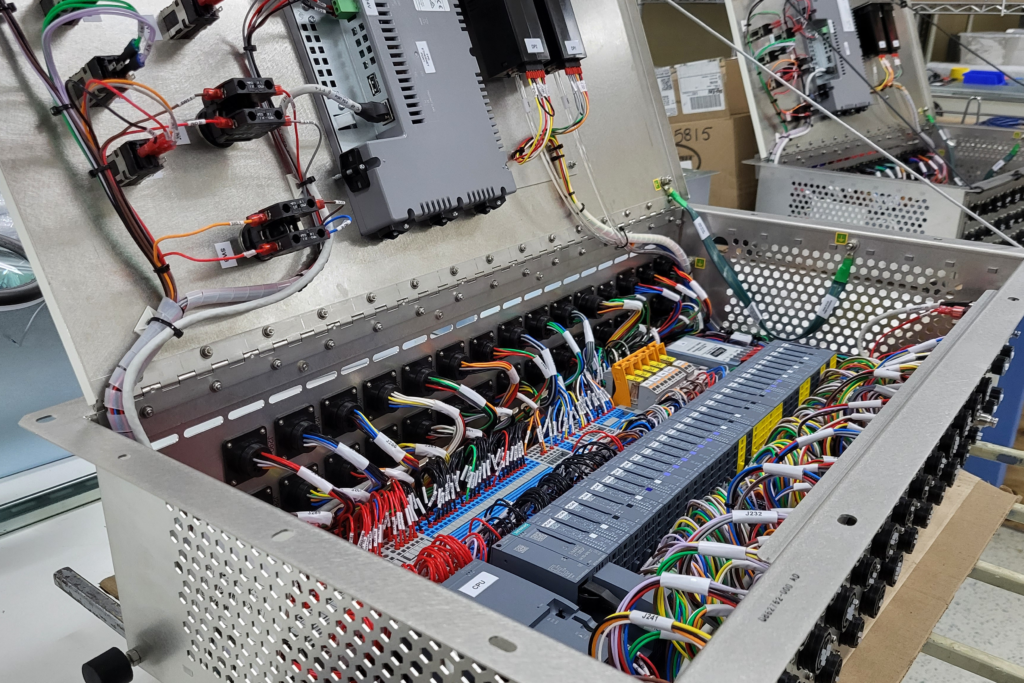

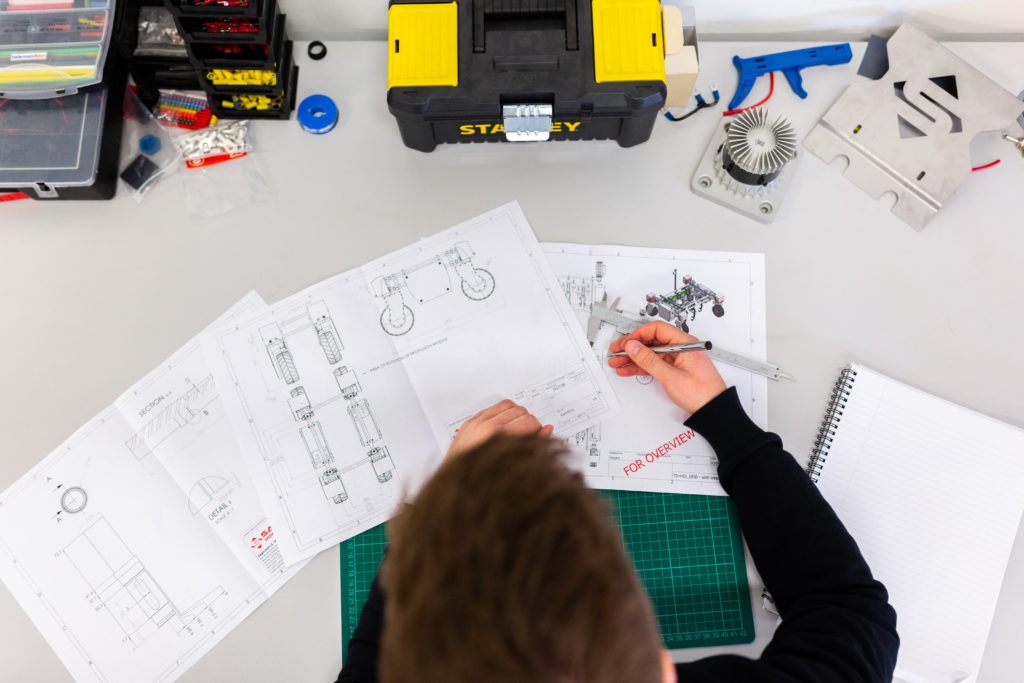

Electro-Mechanical Design, Prototyping, and Assembly

As an ISO-certified company with decades of experience in the integration of electronics and cable assembly design and manufacturing, NPI Solutions can serve your electro-mechanical manufacturing needs from concept to production and assembly. Our engineers can take a project from a basic drawing, turn it into a 3D model, then a prototype, and deliver a fully assembled electronic product. We provide these custom electronic assembly manufacturing solutions to the semiconductor, robotics, and medical device industries. From assembling discrete custom cabling for use in handheld medical devices to manufacturing large-scale electro-mechanical assemblies the size of a room. There are no limits to the electro-mechanical challenges we can solve. If you want to work with expert electrical engineers who can take your project from concept to completion and offer thoughtful design recommendations throughout the process, contact NPI Solutions to discuss your ideas and let us come up with a solution tailored to meet your needs.

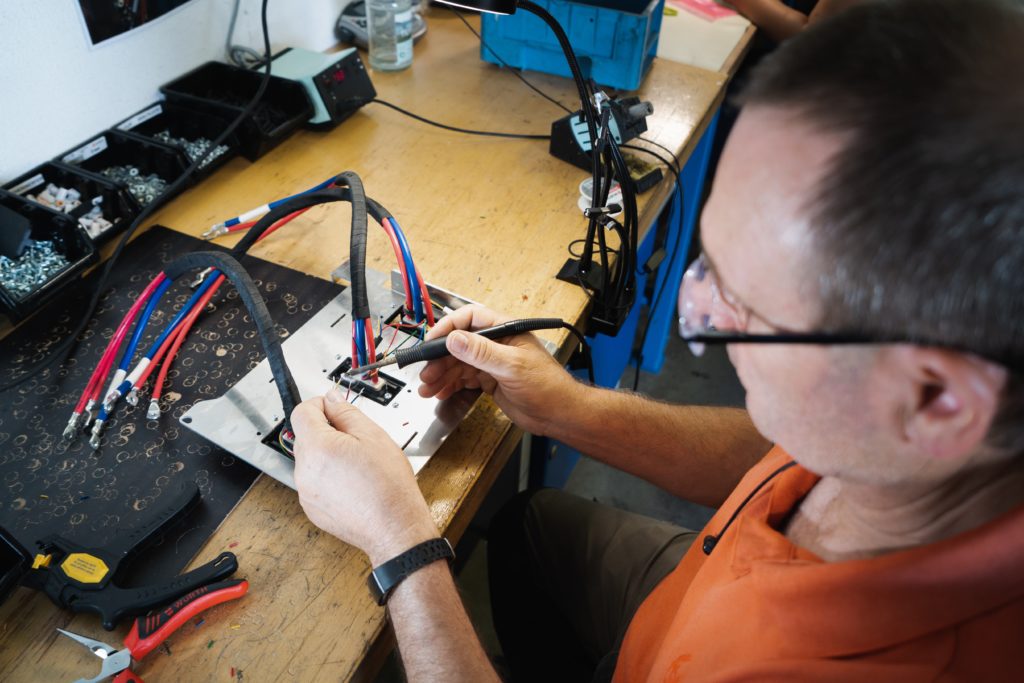

Custom Cable Assembly and Wire Harness Manufacturing

NPI Solutions is a custom contract manufacturer serving industries like semiconductor, medical, industrial, automotive, aerospace, and various others in the production of custom cable assemblies and complex wire harnesses. While our Silicon Valley headquarters has established us as a trusted electro-mechanical component, and cable and wire harness supplier for the semiconductor space, our turnkey design to manufacturing solutions, and quality management systems enable us to work in the medical industry, robotics industry, power distribution, energy industry, and beyond. If you have complex requirements for custom cable assemblies or wire harnesses that will integrate perfectly into your product or equipment, NPI Solutions should be your first call. We specialize in light to heavy-duty cable assemblies involving Coax, Twinax, Triax, and multi-conductor jacketed cables. If you are looking for the right company to provide you with custom electronic assembly manufacturing solutions, NPI is here to help.

On-Site Engineers or Assembly Technicians

If your equipment or design requires privacy only an on-site visit will afford; if the best way to assess your electro-mechanical needs; our experienced team can visit you. We are intimately acquainted with the privacy needs of semiconductor manufacturers, medical device makers, robotics companies, power distribution products, and the various other markets concerned with privacy. An on-site visit from our engineers can prove to be the best way to protect your trade secrets or sensitive government-regulated information. Our service area is generally within 100 miles of our location in Morgan Hill, CA for on-site visits, but we can make accommodations for further distances. If you feel our on-site services would be of benefit to your organization, do not hesitate to reach out regardless of location. If you would like to learn more about our on-site engineering or assembly technician services, quality programs, or any of our other services, click the link below.

ISO 13485 Certified Electronics Manufacturing and Cable Assembly

We believe that quality begins by employing talented engineers and instilling the right values in our team. However, because even the best engineering requires oversight, we have excellent Quality Management Systems in place to provide the necessary controls to ensure quality output at every level. NPI Solutions is ISO 9001:2015 compliant and ISO 13485 certified. From design to assembly, our ISO programs provide us with the processes essential to make sure any design or manufacturing issues are addressed promptly; ensuring only quality products reach our customers

In addition to Our Quality Management Systems, we also maintain a Class 10,000 Clean Room and a Class 100 Flow Hood. This equipment plays an important role in our being able to maintain a clean and safe assembly environment for custom electronics and cables. Our Clean Room and ISO 13485 certification make us well-suited for handling work for medical device manufacturers whose equipment must be free of even the mildest and hardest-to-spot contaminants. When you contact us to provide custom electronic assembly manufacturing solutions, you can always rely on our team to honor our quality guarantees.